EDR Performance KTM 790 890 HD Cylinder head kit!

Daytona Winning solutions!

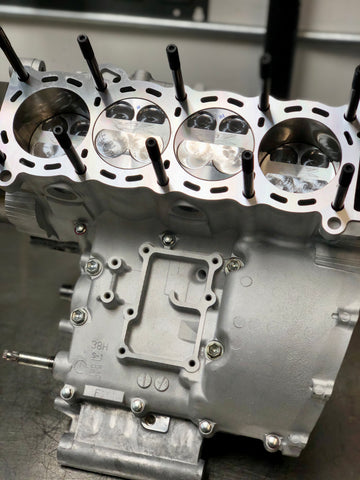

FINALLY A SOLUTION FOR WEAK HEAD GASKETS ON KTM TWINS!!

EDR Performance, the proven leader in KTM 790/890 engine builds & tuning has a solution for one of the weak links on the KTM middleweight twins!

EDR Performance is a leader in KTM 890 Performance & Engine Builds with multiple national championships, Super hooligan National championships, track records, flat track wins, club race wins, Daytona victories and more. EDR built and tuned KTM engines have always been the top placing and highest trap speed KTM's in the MotoAmerica Super hooligans series year after year.

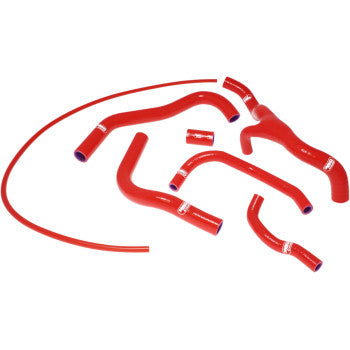

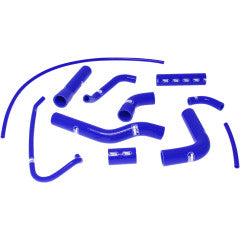

We have found the oem cylinder head bolts lack the strength to hold up to big power and high speeds. Not only in the fact it is a bolt, instead of an actual stud and the material is an extremely low quality at best. For the average everyday commuter they are fine, but for those of you out ripping these things HARD, racing them, track-days and such the head gaskets will start to fail! Our custom EDR HD head stud kit gives you much higher clamping load on the cylinder head so when the pressure is up due to higher heat, more load, higher speeds, more compression and horsepower, your head gasket will hold!

We have found the KTM 790/890 twins to be one of the most reliable engines out there, even our 135+ rwhp ones, however the head gasket does take a beating and typically will last only 1 season at best. Now with our stud kit that is a non issue! Also our stud kit has the ability to be used again and again during refreshes, unlike the cheap oem bolts your stock engine uses that are one time use. If you are going to push your KTM twin the limit, insist on the best, EDR Performance Head Stud kits!

The kit comes complete with all the necessary HD cylinder head studs, HD cylinder head 12pt nuts, HD heat treated cylinder head washers, and both outer cylinder head bolts (HD SS for the smaller M6 outer bolts, nearly 3x over the oem bolts) Also included are detailed install instructions along with the proper recommended thread lubricant as needed. Installation is as easy as the OEM fasteners.

Key points about head studs:

-

More even torque distribution:

When tightening a stud, only the threaded section on the nut is twisting, allowing for more consistent pressure across the clamping surface compared to a bolt which twists along its entire length

Better for high-performance engines:

Studs can withstand higher stress and are preferred for modified engines with increased boost or horsepower where head gasket integrity is critical

Easier reassembly:

Since the stud remains stationary, it's easier to align the cylinder head during reassembly.

FITMENT:

2017+ KTM 790 engines

2019+ KTM 890 engines

EDR produced stud kits are EXCULISVELY designed in house at our location by our head engine developer, Eric Dorn. Eric, who in his 30+ years and thousands of race engines has learned one of the most common failures in modern high performance engines is head gasket failures. One of the main reasons is todays OEM's use inferior, cheaply manufactured head bolts.

EDR produced head stud kits only use premium grade 8740 alloy and a proprietary ARP2000® alloy that are rated far superior to “aircraft” quality alloy steels.

Secondly, each stud is placed vertically into special racks and precisely heat-treated to 190,000 psi for the 8740 material and 220,000 psi for the ARP2000® material. This procedure ensures complete heat penetration and the results are far superior to those lesser quality studs from other manufacturers who just dump pieces in a basket and hope for the best.

Following heat-treat, each stud is centerless ground to make it as close to perfectly concentric as possible. This procedure involves about ten very slight cuts and results in an exceptionally straight part. It’s important to note that lesser quality studs are not even centerless ground – the material is thread rolled in bar stock form (mostly before heat-treat, when the material is easier to machine).

Because EDR produced studs are manufactured to such exacting tolerances, you will note that gaskets and cylinder heads literally glide into position and are perfectly aligned – something that won’t happen with inferior quality head studs.

EDR produced studs are thread rolled after heat-treat, which gives them about 2000% (that’s twenty times) better fatigue strength than those studs that are cut/threaded prior to heat-treat (a very common industry practice). It costs a lot more to do it this way, because it’s tough on tooling, but the results are well worth the extra effort.

These products are intended for closed course off road competition use only. Use of this product for any other purpose is strictly prohibited. Buyer assumes all responsibility to local laws, regulations and use. Racing parts are never legal for sale or use in California or any pollution controlled vehicle.